Determination of Surface Tension

With our test inks, the surface tension of solid materials such as plastics, metals, glass, ceramics, and many others can be reliably determined. This makes it possible to assess the adhesion properties of a surface for printing, bonding, or coating based on its wetting behavior.

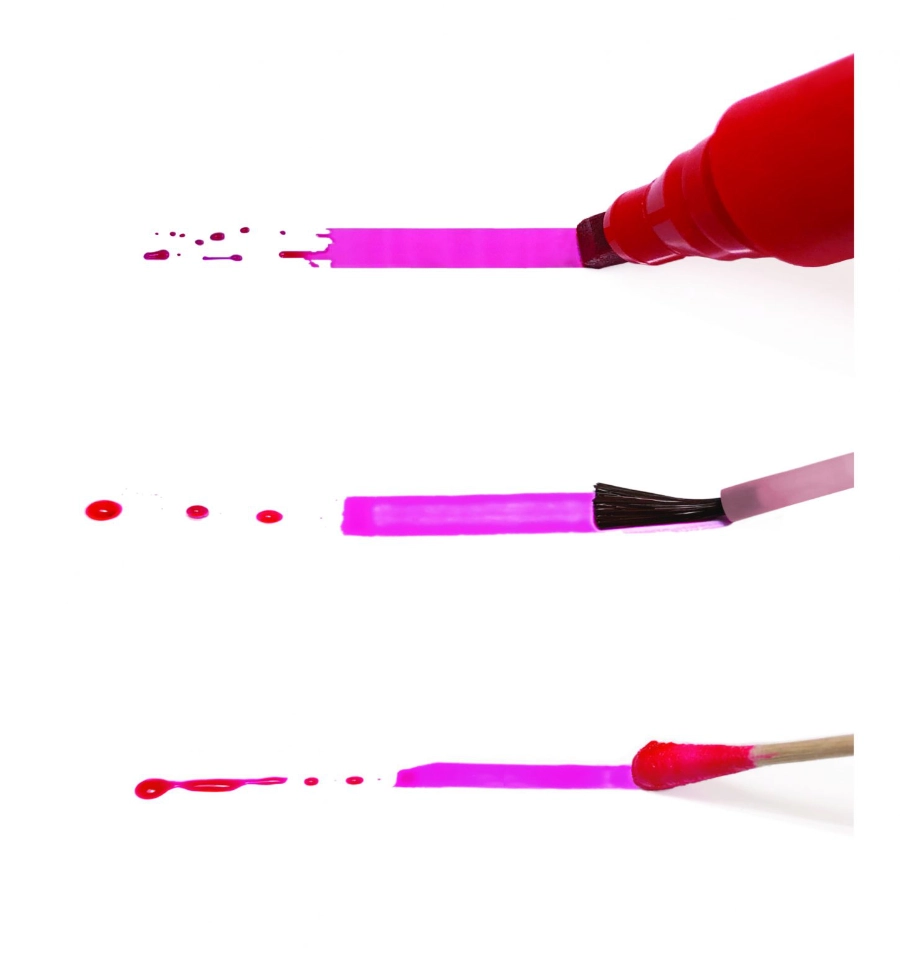

The measurement is carried out by applying the test ink to the surface to be evaluated as a several-centimeter-long stroke and then observing the behavior of the ink line.

If the line contracts within 2 or 4 seconds—depending on the ink specification—the surface tension of the test surface is lower than that of the test ink.

If the line spreads out, this indicates that the surface tension of the ink is lower than that of the surface.

If the line remains stable throughout the observation period, the surface tension of the surface matches the value of the test ink or is slightly higher.

Testing of a plastic surface with PINK 38 Jumbo

In this application example, the PINK 38 Jumbo test pen is used to check the surface tension on black PE plastic.

Testing of a metal surface with PINK 10 ml

In this application example, is tested with test ink PINK from 10 ml bottles with cotton swabs. Take a new cotton swab after each use.

Check metal surfaces for cleanliness

In this application example, is tested with test ink PINK from 10 ml bottles with cotton swabs. Take a new cotton swab after each use.

Testing of a polyolefin film for 38mN/m

RAPIDTEST 38® serves to check if the treatment of polyolefins (polypropylene, polyethylene, polybutylene) has shown an effect onto the material. A stroke of the pen leaves a full line on thematerial if thematerial’s surface tension has a value of 38mN/m or more. The fluid applied to the surface will dry within seconds, it does not need to be wiped off anymore.